What are the Components of a Centrifugal Pump?

Fristam Centrifugal Pump

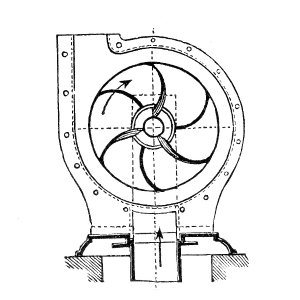

A centrifugal pump converts mechanical energy into hydraulic energy using centrifugal force applied to the fluid. This type of pump is the most common used in sanitary and industrial settings and are ideal for transferring high volumes of fluids and for transferring fluids from a lower level to a higher level.

Waukesha Centrifugal Pump

Centrifugal pumps often are seen in the food and beverage production and most often associated with thinner based product.

The major components of a centrifugal pump:

• Impeller: An impeller transfers rotary velocity from the motor to the liquid, generating pressure and pushing liquid through the discharge port.

• Shaft: The impeller is mounted on a shaft. The shaft transmits torque from the motor to the impeller.

• Casing: The casing contains the liquid and directs flow in and out of the pump.

• Packing Rings: Centrifugal pumps are outfitted with packing rings or a mechanical seal, which prevent leakage of the pumped liquid.

• Bearings: Bearings constrain the relative motion of the shaft and reduce friction between the rotating shaft and the stator.

• Intake & Discharge Ports: Fluids are drawn in and released through the pump’s ports.

Pump strength is increased by adding faster, larger or more impellers, depending on the viscosity of the liquid and flow rate needed.

Amco Centrifugal Pump

Lincoln Suppliers is dedicated to stocking top brands of centrifugal pumps. Our knowledgeable staff understands every model—helping your business make the most informed buying decision possible. Want to learn more? Give our team a call at 800-622-8425 or request a free quote today.